How Lean Scheme can help manufacturing MSMEs drive growth, compete globally

The Lean Scheme was launched in India in 2009, and underwent a significant overhaul in 2013. The primary objective of implementing the scheme was to chart a roadmap for MSMEs towards global competitiveness.

The Micro, Small, and Medium Enterprises (MSMEs), which are the backbone of the Indian economy, contribute over 33% to the nation’s GDP. They represent a substantial 28% of the manufacturing sector, according to MSME annual report and boasting close to 200 lakh production units.

In order to support these businesses, the Government of India, in tandem with the Ministry of MSME, has been rolling out various initiatives. One such initiative is the MSME Competitive (Lean) Scheme (a component of MSME Champions Scheme), which is poised to turbocharge the production capabilities of MSMEs.

The scheme aims to help MSMEs enhance productivity, efficiency, and competitiveness by reduction of wastages in processes, inventory management, space management, energy consumption, etc.

While the Lean Scheme propels Indian MSMEs towards global competitiveness, its visibility and implementation still remain low. Even those who are cognizant of its existence often find the overhaul process daunting and become resistant to implement it.

Lean Scheme in India

Lean Scheme, which is based on the Japanese methodology, is the concept of efficient manufacturing, and originated from Japanese automotive manufacturer Toyota. The mechanism helped Toyota in reducing wastage by focusing on reducing difficult jobs.

Today, Lean principles have gained global recognition and are implemented worldwide.

In India, Lean Scheme was launched in 2009, and underwent a significant overhaul in 2013. The primary objective of implementing the scheme in India was to chart a roadmap towards global competitiveness for Indian MSMEs and the very mindset of manufacturers.

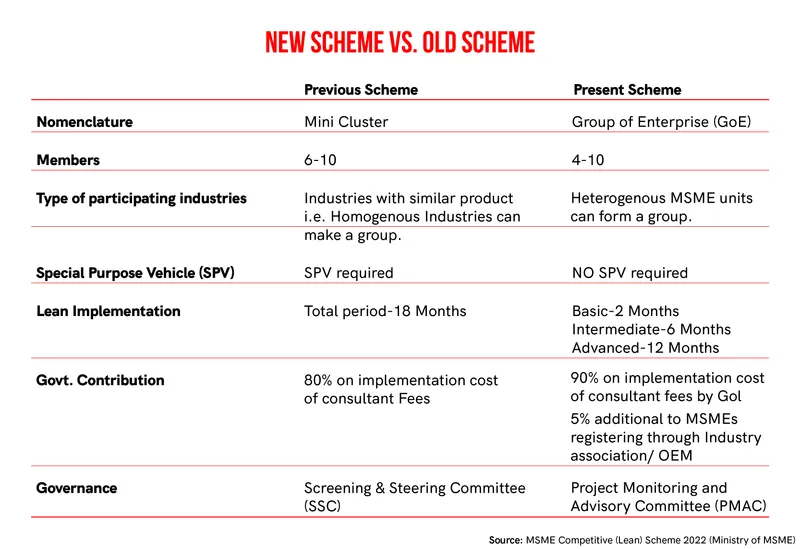

Comparison of Lean Scheme: New vs Old

“This approach to production emphasises the elimination of resource expenditure for purposes other than delivering value to the end customer, deeming such activities wasteful,” says Dr V Rama Krishnan, Deputy Director, MSME DI, Govt. of India.

The Lean Scheme Manufacturing programme in India actively engages business consultants to guide MSMEs in enhancing their operational efficiency. To facilitate this, MSMEs collaborate with the Quality Council of India (QCI), which in turn selects various business consultancy firms to support MSMEs by forming distinct enterprise groups.

In March 2023, the central government launched the revamped MSME Competitive (LEAN) Scheme to make it more beneficial for enterprises and stakeholders.

The scheme will not only attempt to improve quality, productivity, and performance, but also the capability to change the mindset of manufacturers, said Narayan Rane, Union Minister for Micro, Small and Medium Enterprises, at the launch event.

“There is an appetite for this scheme,” Ateesh Kumar Singh, Joint Secretary, Ministry of MSME, tells SMBStory. Singh says that the previous scheme had its own set of problems, and hence, the new scheme has been introduced where the Ministry has cut down cumbersome levels to make the processes easier.

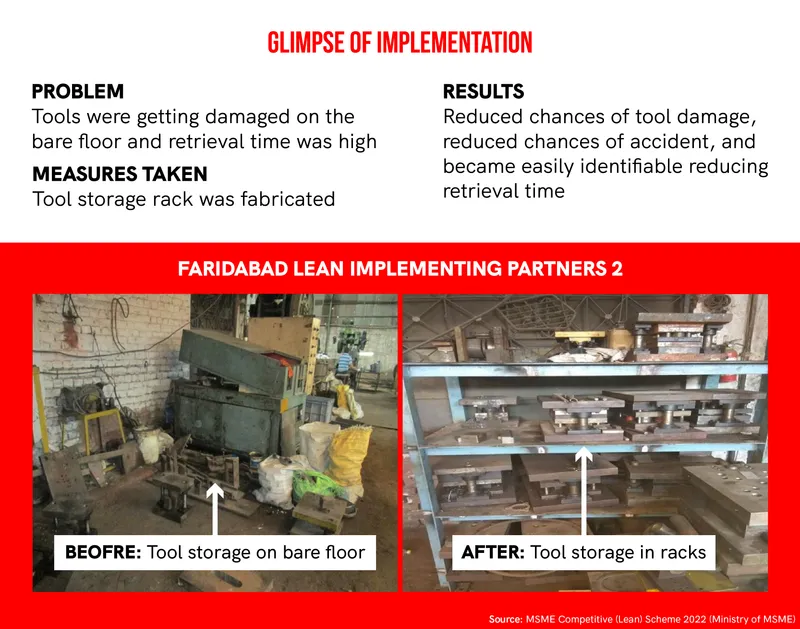

Implementation of Lean scheme

Aniket Bagde, CEO of AB Associates in Nashik and a Lean Consultant for MSMEs, emphasises that the Lean Scheme isn't merely transactional, but transformational, and aims to minimise waste and enhance profitability.

He explains that the programme comprises of three stages--basic, intermediate, and advanced--spanning a 20-month duration, with MSMEs deciding how far they wish to progress.

“Policy implementation in India is tough,” Bagde says, adding that MSMEs that are adaptive take advantage of these schemes.

Shantanu Mazumdar, Director, Business Development at Mufront Technologies, which has adopted the Lean Scheme, says that after taking up the lean model in the business, his perspective has also changed.

“Recently, we shifted our plant from a 4,200 sq. ft space to a 7,000 sq. ft space. Through the Lean Scheme, we are able to modify processes such as segregating assembly lines that have increased production capability and brought in equal manpower allocation, etc., which was not happening before. This time our production is likely to increase 2.5X to 3X,” Mazumdar unveils.

He says that they are also working on altering HR and admin processes as per the Lean Scheme module, which they are yet to implement.

“All the micro, small, and medium enterprise units can take part in this scheme. The government hasn’t put any cap or budget as we want more people to be a part of this scheme so that as India, we can increase our global competitiveness,” Krishnan says.

However, there are a majority of them who do not want to alter existing processes considering it a hassle and miss out on advantages.

Government initiatives

In the initial phase of the scheme, the government covers 90% of the programme costs. In the subsequent years, businesses are required to cover the consultant fees if they choose to continue with the programme.

The government has also given an additional 5% for enterprises that are part of Scheme of Fund for Regeneration of Traditional Industries (SFURTI) clusters, owned by Women/SC/ST and located in the Northeast region.

Drawbacks and challenges

The Lean Scheme has the capacity to grow a company’s performance by 3X says Bagde; however, the question remain--whether it will benefit micro enterprises whose end turnover is not more than Rs 5 crore.

“Changing systems will not be easy,” says Mukesh Mohan Gupta, President of Chamber of Indian MSMEs. According to him, micro enterprises run as a ‘one man show’, and to adopt a scheme that will change their existing processes will turn them off. Also, the cost involved can make them resistant since most of these enterprises lack funds.

However, on the other hand, Krishnan points out that the government’s vision is to pave the path of growth for these micro enterprises.

“In the initial phase of this scheme, enterprise owners will make a modest financial contribution, typically amounting to a few thousand rupees. This nominal cost is applied because items or services offered completely free often lack perceived value and we want these enterprises to come forward and be a part of the scheme,” Krishnan explains.

Taking Tirupur’s MSME clusters as an example, he highlights that earlier, MSMEs in the knitwear capital of India were not much aware of the certifications and benefits of streamlining processes, but after they adopted the scheme, there are seeing a difference.

According to Krishnan, the micro units in Tirupur and other MSME dominant states like Odisha, Bihar, Karnataka, Maharashtra, etc., who are following Lean modules, are now able to understand sustainability, importance of process-driven business operations, quality management, etc., and all this will help in boosting the quality, and in turn increasing their exports.

But still, awareness and strong implementation of the Lean mechanism is something where MSMEs are behind.

“Recognising the scheme’s potential in the manufacturing sector, our focus should now revolve around enhancing awareness,” says Jayanth Murthy, Joint Managing Director - South Asia & Africa at Kaizen Institute, a global organisation that provides consulting and training services to enterprises.

He adds there is a need to increase awareness among MSMEs about the potential benefits that Lean techniques can bring to their businesses, which may be followed by efforts to enhance their understanding and knowledge of these techniques and their effective deployment.

“The scheme has promising potential, which is reflected in the 20% increase in the productivity of the participating units,” Murthy says.

The journey of acquainting the MSMEs to the Lean scheme has only just begun. Drawing attention, Krishnan says, “you will see that in the next 10 years, the industry map of India will change, and for good.”

Edited by Megha Reddy