This 'Made in India' bearings manufacturer exports to 30 countries, including China; clocks Rs 2,511 Cr turnover

National Engineering Industries was started by BM Birla to make India self-reliant in manufacturing bearings. Today, the company manufactures around 20 crore bearings a year for automotive and industrial segments, and exports to 30 countries, including Germany, Japan, and China.

In 1946, when India was beginning to find its footing across the world as a free nation, industrialist BM Birla was way ahead thinking of making this country self-reliant in the industrial manufacturing sector.

He found the opportunity in a small, yet indispensable mechanical component — bearings. Bearings — small and large — are widely used in the automotive and industrial sectors as it reduces friction between the moving parts, thereby achieving the desired motion in machines.

However, at the time, this essential component was imported from abroad, causing distress to domestic manufacturers. In a bid to make an ‘Aatmanirbhar Bharat,’ BM Birla started a bearing-manufacturing company called the National Bearing Company Limited (NBC) in 1946.

Chandra Kant Birla, Chairman, CK Birla Group

Becoming self-reliant since 1946

NBC — which was later changed to National Engineering Industries (NEI) — was started with an initial investment of Rs 80 lakh, with a sole production unit in Jaipur. In 1950, the company began with manufacturing 30,000 cylindrical roller bearings, which it supplied to the Indian Railways as well.

NEI is the flagship company of the $2.4 billion CK Birla Group. The conglomerate, led by BM Birla’s grandson CK Birla — also has businesses in technology and automotive, home and building, and healthcare and education segments. Orient Electric — a known Indian consumer electricals company — is also part of the CK Birla Group.

Over the years, NEI has become a global bearing manufacturer and exporter out of India, clocking Rs 2,511 crore turnover in FY19. At present, it manufactures about 20 crore bearings in 1,450 sizes in a year from five manufacturing units spread across Jaipur, Gujarat, and Haryana. In fact, the production facility in Newai, Jaipur, was started as an all-women unit in 1980.

The company also exports to 30 countries, including Germany, South Africa, Japan, and China. It claims to report 20 percent of its revenue from its export business. Recently, NEI acquired Slovakia-based Kinex Bearings — a water pump and industrial bearings manufacturer.

“The vision of our founder was to make India self-reliant and also contribute to the causes of nation-building and mobility in those times,” says Rohit Saboo, President and CEO, NEI.

An employee of CK Birla Group since 1994, Rohit started leading the R&D vertical in 2000 and was appointed the CEO of NEI in 2008.

NBC or NEI exports bearings to 30 countries including China

Digital transformation

For the 74-year-old bearings manufacturer, Rohit says, digital transformation is the way forward. The company has invested extensively in three areas — R&D or quality of products, people, and technology.

These steps have helped the company to keep up with the increased demand over the years, and compelled it to focus on its quality management and other areas more closely.

“Bearing is a component that requires precision. Hence, most of the critical machines are imported from European countries or Japan,” Rohit says, adding that some of the machines are developed by Indian manufacturers as well.

With the help of technology, NEI has been able to digitise its supply chains, optimise inventory, and predict machine breakdowns using data analytics.

In fact, amidst the coronavirus pandemic — when most of the businesses had come to a standstill — through a digital platform, the company was able to gather a pool of ideas to cope with the situation and was able to work on some massive cost-reduction strategies as well.

Rohit claims that NEI aims to fully digitise its manufacturing and non-manufacturing operations in the coming years.

NBC or NEI has five factories in India and recently acquired Slovakia-based Kinex Bearings

India’s bearing industry

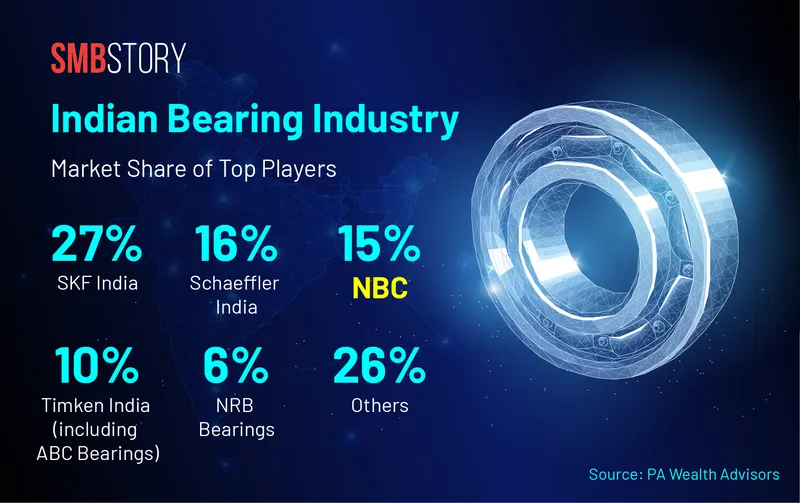

According to Rohit, the Indian bearing industry is worth Rs 13,000 crore, which is equally captured by the automotive and the industrial sectors. He believes that India’s manufacturing sector needs a boost, and the government needs to frame appropriate policies to bring down the overall cost of manufacturing in the country.

While 95 percent of the automotive bearings are being made in India, only five percent are imported.

According to a report by Business Wire, the Indian automotive bearing market was valued at Rs 70 billion in 2019 and is estimated to reach Rs 156.8 billion by 2024, registering a CAGR of 18 percent between 2020 and 2024.

On the other hand, since the requirements are diverse in the industrial sector, about 70 percent of the bearings are imported.

At present, it produces and exports a host of bearings, including deep groove ball bearings, spherical roller bearings, and tapered roller bearings — which are extensively consumed by the automotive, railways, and industrial sectors.

Over the years, NEI has collaborated with foreign players like Brenco Inc. (US), The Hoffman Manufacturing Company (UK), and Bower Roller Bearing Company (US) to expand its portfolio. In India, the company competes with players like Schaeffler India Ltd., SNL bearings Ltd., SKF Bearings India Ltd., Timkin India Ltd. (a joint-venture between TISCO and The Timken Company), and a few others.

Adapting to changes and future plans

For the last 74 years, NEI has been witness to many economic, political, social, and policy changes in the country. However, the company has managed to keep pace with the changing times by “plugging in the gaps within the company as and when required,” and “forging relationships with its customers.” “We have given them the confidence that we can be their long-term partners,” Rohit says.

NEI also plans to dive into India’s emerging electric mobility sector. According to a report by PA Wealth Advisors, growth opportunities for the automobile bearing industry will increase on the back of the growing demand for automobiles in India, rise in the income of the bourgeois, especially the young population, and lastly on the fact that India is expected to become a global leader in shared mobility by 2030, providing opportunities for electric and autonomous vehicles.

“We will be developing more bearings for the EV sector, such as smart and high-speed bearings,” Rohit says.

The company registered “zero business for two months,” owing to the pandemic and slowdown in the automotive sector. However, NEI’s business started picking up once the nationwide lockdown started lifting in phases.

With the auto sector seeing a speedy recovery in the past few months, Rohit believes NEI will reach its pre-COVID-19 levels by next month. Going forward, NEI also aims to double its turnover in the next five years.

Edited by Suman Singh