[Techie Tuesday] Meet Prashant Gade, the assistive-tech inventor whose life’s purpose is to leave no person with disability behind

In this week’s Techie Tuesday, we meet Prashant Gade, Founder of Inali Foundation, who is widely acclaimed for leveraging tech to give thousands of people without upper limbs a new lease on life.

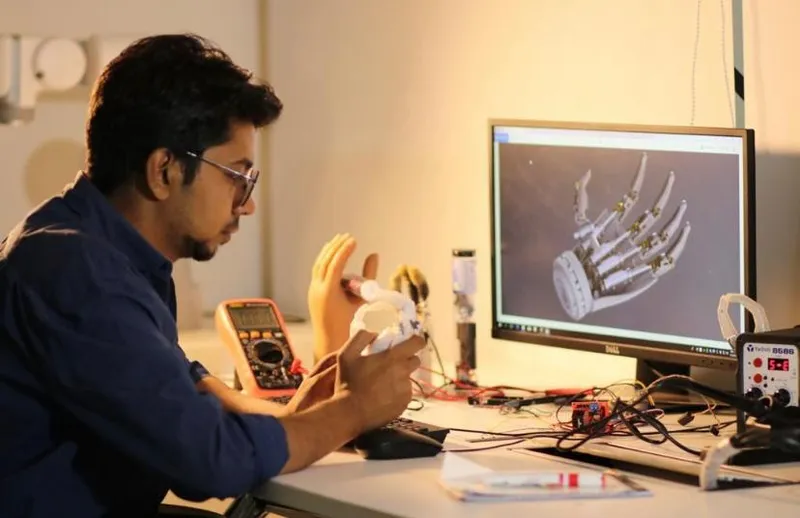

Prashant Gade — the founder of Inali Foundation, a not-for-profit enterprise that provides low-cost prosthetic arms — is widely acclaimed for leveraging tech to give thousands of people without upper limbs a new lease on life.

Prashant Gade's life purpose is to make sure no person with disability is left behind.

By designing and perfecting affordable 3D-printed prosthetic arms, the assistive tech inventor is making it possible for ordinary people who have lost both or either of their upper limbs in accidents or didn’t have them since birth to finally use their hands after years of feeling excluded.

But this techie is a philosopher first and an inventor second. The common driving factor in both roles being his resolve to fulfilling a larger purpose in life: helping others and enabling lives.

Through Inali Foundation, he has been able to do just that: enable more than 3,500 people to work and live life independently by giving them prosthetic arms for free.

26-year-old Prashant confesses his greatest happiness today comes from being able to enable lives through technology and the work he does.

He says, “When I started out, I never thought this will grow in such a big way and that so many people will benefit. But today, I’m happy, not just because there are so many people benefitting from this, but because I got the opportunity to help others and find my purpose in life.”

Prashant has enabled more than 3,500 people to work and live life independently.

Early inspirations: his grandfather and Pranav Mistry

Even as a curious, young boy growing up in Khandwa, Madhya Pradesh, Prashant found himself plagued by questions around the purpose of life, and in particular, his own. Even then, the philosophical questions came first and they prompted the invention. How does that machine work? What do I need to do to make it work better? What is the mechanism behind this tool or machine?

Inspired by his grandfather, a taxi driver who loved tinkering with his vehicle and fixing anything on sight, Prashant spent many a hot lazy Khandwa afternoon making small coolers out of cardboard, small toy motors, and oil bottles.

Making these coolers were a welcome distraction for the eight-year-old Prashant, who soon found his curiosity building with each new project he worked on with his grandfather. Those were not the days of Google, so he had to rely on his own curiosity to unravel new truths about the science and tech powering certain motors.

He soon developed a fascination for robots and how they can make your life easier. The first robot he made was a line follower, where you place a robot on a line you’ve created and it follows that exact same line or path.

His interest took him to an institute in Indore where they were teaching simple robotics to kids. More questions followed when he saw the professor at the institute demonstrate a small robot move in a particular path.

They ranged from basics such as, “What is a robot? What is a machine? What’s the difference between the two? Is a fan also a robot?” to other more complicated ones such as “How can I automate my home? How can I ensure a fan starts when the temperature exceeds a certain level and stops when it normalises? How can I automate my home so that when people aren’t at home, then all gadgets are turned off?”

Later, of course, Prashant discovered all of this was down to engineering. He began working on small projects like this but found that he was most influenced by every day problems he saw that could be solved through engineering.

For example, when he would see his grandparents watering the plants while gardening on a hot day, his immediate thought would be that that’s a problem he needs to solve by automating the process.

Prashant says his early inspiration and insatiable curiosity was sparked by his grandfather. Pranav Mistry, the inventor of sixth sense technology who is currently CEO of NEON and CEO of Samsung’s STAR Labs, comes a close second. As a 10th standard student, Prashant was fascinated with Pranav’s 2009 TED Talk where he demoed several tools that he had invented to bring the physical world to interact more seamlessly with the digital world.

“That was the second point in my life that I was convinced that I wanted to do something like this. I thought the technology and the inventions Pranav demonstrated were so good and that they had the potential to change everything around you. So, he really ignited a spark in me, and I follow him and his work a lot,” says Prashant.

Finding his life’s purpose

Indeed, that search for his life’s purpose — much like that of a monk in search of the meaning of truth, Prashant himself confesses — began early for him. It eventually brought him to the first turning point in his life: his meeting with seven-year-old Shreya, who was born without her upper limbs.

Prashant was working on his robotics course project at the time. Inspired by Nicholas Huchet from France, who had made a bionic arm for himself when he lost his hand in an accident, Prashant made his first prototype, a prosthetic arm that he was testing on real patients.

After meeting Shreya, Prashant desperately wanted to help her. He thought of gifting prosthetic arms to her and reached out to a prosthetic company to buy them. However, he was shocked to learn that the arms would cost Rs 24 lakh. This was unaffordable, especially given this was not a one-time expense as the arms would have to be regularly changed and fitted for a growing child.

Shreya’s plight made him wonder about the plight of thousands of others like her who may be unable to afford these prosthetic arms. He then learnt that more than 40,000 people in India lose their upper limbs every year. Of this, 85 percent continue to live without any solution as they cannot afford the exorbitant cost currently being charged for each arm.

“I started thinking about how many people need this device. The number was really shocking because I realised a lot of people needed this prosthetic arm but can't afford it. And if they can't afford it, nobody is going to make the solution. I thought maybe this could give answers to my questions about the purpose of my life. I don't know how and why I got the feeling inside that this is the thing that I was looking for and I jumped into it,” says Prashant.

Since then there was no looking back. The next day, Prashant — who was working as a robotics engineer at the time — quit his job and called his parents to tell them that he now wants to build affordable prosthetic arms to help those in need. His parents advised against it, saying he should first earn a living before moving into social work, but Prashant’s mind was made up.

Shortly thereafter, he began working on these prosthetic arms. In 15 days, he had designed one hand. Since money was scarce, he tried to raise some funds through a crowdfunding campaign. While the campaign did not yield a lot of funds, Prashant got a call from a Jaipur-based NGO, asking him to come to Jaipur and show them the hand he had designed.

After his meeting, Prashant received a small grant from the organisation to make seven such prosthetic hands. With this grant, he started up in a new city, renting a small room and walking 10 kilometres every day to the NGO so he could save his bus fare.

At the NGO, he would try out the hands he was designing with different patients. Each patient offered a different feedback.

The many iterations

The first robotic hands he made could be controlled with the other hand through a glove. He found that for many of the people the first version was very complex because they needed to control the arm with their other hand while driving tractors or bicycles. So with time, he created a different design.

The second design had a small motorbike glove that goes over your wrist. By bending your wrist or opening it, the movement sends a particular signal for closing or opening your robotic hand. However, most people who needed these hands were using them to ride their bikes; this was creating problems for them because one needs to move their wrists frequently when riding a bike.

“So, that's when I came up with another design where I can control the hand with an elbow. The same string or same belt can be made and whenever you move the elbow, there is a tension in the spring which activates the other hand,” he explains.

With this too, he found flaws because patients had to depend on somebody else. “Next, I came to the shoulder. Once you move your shoulder up, the hand opens and when you move your shoulder down, it closes. So, I put a sensor that takes the distance, displacement, and speed of your shoulder movement. And based on that, it activates the hand.” With this version too, the challenge was the dependency patients had on others when wearing it.

“With time, I created a few designs but every time the director of the NGO said it was too expensive,” Prashant recalls.

This, despite the fact that he had gone from creating a robotic hand that cost Rs 1 lakh — which was still considerably lower than the Rs 12 lakh per hand that was being charged by prosthetic companies — to one that cost Rs 50,000 and then Rs 20,000.

“Even with all these cheaper versions, I was getting his no every time. But for me, there was some money involved in making this so I could not make it at a very cheap rate. At the time, I thought it is not possible to make it any cheaper,” Prashant shares.

Five months passed since moving to Jaipur and slowly his money had also run out. One day, he decided to ask the director how much he can afford to pay per hand. To which the director replied saying $100.

“I was shocked. I was talking about hands which cost Rs 12 lakh and how can you expect a hand which is about $100 or Rs 7,000,” Prashant remembers thinking to himself at the time.

But there was no way to go back on this. He was convinced he had to move forward and find a solution that allows him to create one at an affordable rate.

The only way forward, Prashant says, was to bring out the kid in him who used to love making things from scratch. “Because if you ask kids to go and make something, they never say they don't know how to do this.

They don’t make excuses about not being an engineer or about not knowing technology. They simply go and find out how to make those things. I think the best engineer in this world is a small kid. He doesn't know anything about tech. But he knows how to do it,” Prashant says.

Frugal innovations

And so, Prashant started thinking like a kid. And also like a boy from a middle-class Indian family, where parents teach you one thing: Jitni chaddar hain, utna pair phelao, which is Hindi for, “do things that are under your capacity; don't go beyond imagination”.

“This is where frugal innovations come in. How to do more when you have less. That’s the thing I learnt. I thought if I can actually observe all those things near me and start using those things to make the hands,” recalls Prashant.

As someone living in Jaipur at the time, Prashant saw a lot of puppet shows where they used to make them dance by controlling these threads on the toy’s fingers.

“The human hand is made up of a lot of muscles. Every muscle is connected to every finger. You’ll find that if you pull a single muscle, it seems like a string and is connected to a particular finger. Most of the expensive prosthetics arms come with small motors which can actually move the fingers but those are expensive. I didn’t have enough money. But I did have a badminton racket,” Prashant says.

So he pulled out all the threads in the badminton racket and put it inside the prototype and connected it to a small single motor.

“Whenever the motor revolves, the threads get winded over it and the finger gets pulled down. To move it back, I put some elastic bands behind to take it back. So, whenever the motor releases the threads, the bands pull back and it opens up,” he explains.

For the fingers, Prashant was inspired by the lever used in the JCB toys to lift things. But Prashant was visualising the lever in a different way.

“For me, it looked like a finger and not a lever. The whole JCB toy cost Rs 180 and the lever is a small mechanism that can be used for different stuff. But for me, if I could make the same mechanism look like a finger, it would be affordable. So, I made the same mechanism and made the finger out of it. And then I put the threads from the badminton racket and connected it to a motor.”

Next, he had to come up with the arms. Most arms come with a silicon fingertip because the human hand has skin to grip objects but prosthetic arms do not have that grip. To have that grip, Prashant needed silicon tape, which is expensive and something he couldn’t afford.

Fortunately though, Prashant discovered yet another way around this to ensure a cost-effective way for the prosthetic hands to have a grip.

“I was sitting and thinking about this grip and my hand was on a hot water bag. I thought this bag is giving me a grip so why not try this. I cut the whole hot water bag into a few pieces and put it on the fingertips and somewhere on the palm. And what I got was a different grip, similar to the way a silicon fingertip could give me,” Prashant says.

With that, Prashant had everything he needed to make a low-cost prosthetic hand. Within the next 20 days, he went back to the director to tell him he was done with designing the hand. It was priced at just $75 (or Rs 5,500) a hand, much lesser than the budget the director had set for him at $100 (or Rs 7,000) per hand.

There was only one more thing remaining: how to make these hands at scale as Prashant did not have any 3D printing machines.

“In a moment a miracle happened. I got an email from a professor in the US, who was doing a conference on biomedical devices. He said he saw my video on YouTube and invited me to the conference,” Prashant recalls.

There, Prashant gave a talk, after which he was asked how they can help him out. While he didn't ask for any money, he explained how important it was to make this device in India and other developing countries because of the sheer number of people in need of these hands.

“The next day, the professor came to me and said we are giving you 10 3D-printing machines. I started crying,” Prashant says. Soon after, he returned to India and started the Inali Foundation — named after the love of his life, Inali Wahane, who Prashant says unquestioningly believed in his ability to fulfil his life’s purpose.

Inali, he says, means a start toward a new change. “I feel she is the person who made me what I’m today. That's why I devoted this name to her. I got somebody who said you can always do something. And that's why I cannot quit on somebody like her. That's why I devoted this foundation in her name,” Prashant adds.

Inali Foundation

From 2015 to 2018, Prashant spent his time devoted to research and development — something he continues to focus on at Inali. In 2018, Inali was registered as a Section 8 company.

Today, Prashant has three different designs. The first one is a simple, tap-based hand. As 90 percent of the people who come to Inali want to ride their bikes, the team came up with a simple solution where you just need to tap the hand once. Once you tap it close, you can hold the handle until you tap it again to open your hand.

The second design is a myoelectric arm that works with a signal from your brain. Whenever a person thinks of moving his finger, his brain sends some electrical pulses. “You have two sensors that are myoelectric sensors, which take signals and give them to the processor inside the hand and make those fingers move,” he adds.

The third one is an advanced, gesture-based hand. “You need to have a sensor in your ankle joint. Whenever you move your ankle, there is a particular gesture that we have placed. We teach the patients to do certain gestures. Once you do it, it sends a signal through Wi-Fi to the receiver of the hand. After the receiver receives those signals, the signal gets processed again and the hand moves,” Prashant explains.

With the gesture-based hand, people don’t need to rely on another hand to touch it or on high-electric sensors for it to work. Across the world, these gesture-based hands are priced at anywhere between $10,000 to $120,000, but in India, the hand costs merely Rs 25,000. And even with this, Prashant and his team are trying to make it more affordable.

Today, he says the Dassault Systemes and Infosys Foundation-backed Inali Foundation is on a mission to ensure there’s no last person standing with disability.

“Now, the goal is not to make a $75 prosthetic arm alone but also to create something which can solve more problems. Or maybe, give a person independence to get back to life,” he says.

Edited by Saheli Sen Gupta

![[Techie Tuesday] Meet Prashant Gade, the assistive-tech inventor whose life’s purpose is to leave no person with disability behind](https://images.yourstory.com/cs/21/604090802d6d11e9aa979329348d4c3e/TT-April-6-02-1617644679599.png?mode=crop&crop=faces&ar=16%3A9&format=auto&w=1920&q=75)

![[Techie Tuesday] After building systems at Trilogy, Myntra, and Amazon, he aims to simplify financial inclusion with Chqbook](https://images.yourstory.com/cs/2/a9efa9c02dd911e9adc52d913c55075e/TT-22-1616401218891.png?fm=png&auto=format&h=100&w=100&crop=entropy&fit=crop)

![[Techie Tuesday] Zynga co-founder and startup investor Justin Waldron's game plan with PlayCo](https://images.yourstory.com/cs/2/a9efa9c02dd911e9adc52d913c55075e/Techie-Tuesday-1615827917111.png?fm=png&auto=format&h=100&w=100&crop=entropy&fit=crop)

![[Techie Tuesday] Meet Recko CTO Prashant Borde, who earlier founded Myntra-acquired GridAnts](https://images.yourstory.com/cs/2/a9efa9c02dd911e9adc52d913c55075e/Techie-Tuesday-1-1609761485042.png?fm=png&auto=format&h=100&w=100&crop=entropy&fit=crop)

![[Techie Tuesday] From an intern at Microsoft to building the core financial structure of a fintech startup, Brex CTO Cosmin Nicolaescu’s tech journey](https://images.yourstory.com/cs/2/a9efa9c02dd911e9adc52d913c55075e/Techie-Tuesday-30-1606734835907.png?fm=png&auto=format&h=100&w=100&crop=entropy&fit=crop)

![[Techie Tuesday] Meet Laks Srini, the techie who co-founded Zenefits and is now building ZeroDown](https://images.yourstory.com/cs/2/a9efa9c02dd911e9adc52d913c55075e/Techie-Tuesday-nov-1605516060371.png?fm=png&auto=format&h=100&w=100&crop=entropy&fit=crop)